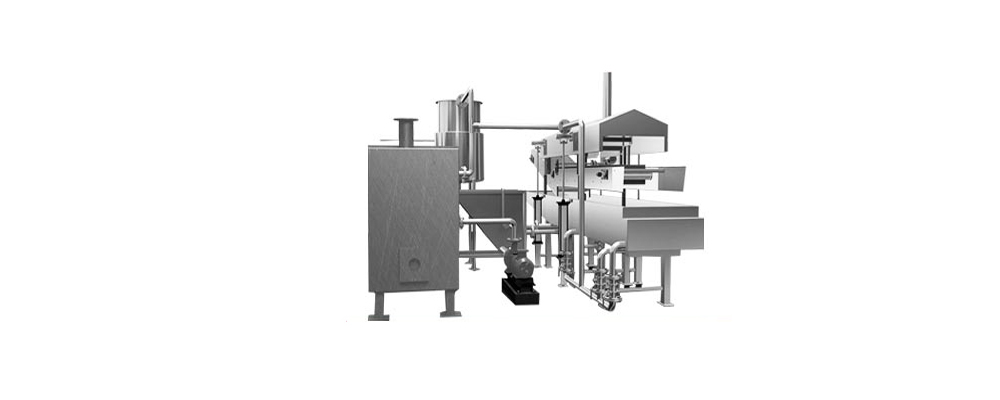

Continuous Frying System with Diesel or Wooden Heat Exchanger

- Also available with Wooden based Thermic Boiler and Thermic Heat Exchanger

- Available in 300 Kg/Hr, 500 Kg/Hr and 1000 Kg/Hr Production

The Namkeen continuous frying system is suitable for all kinds of Besan based products like Sev, Ghathiya, Papdi, Ratlami, Bhavnagri And other floating products.

The Frying system has following features:

- Production Capacity: 300-350 Kg/Hr (Besan Sev, Ghathiya etc)

- Power Consumption: 8.5 HP

- Fuel Consumption: 11-13 Ltr/Hr

- Oil Holding Capacity: 275 to 400 Litres ( Acording to production Capacity.)

- Oil Holding Capacity: 275 to 400 Litres ( Acording to production Capacity.)

- Oil Holding Capacity: 275 to 400 Litres ( Acording to production Capacity.)

- Complete Material of Construction is SS 304 Grade

- Pneumatic Conveyor Lifting Arrangement for easy cleaning

- Heat Free working Environment

- Zero Maintenance Fryer

- Optimal oil turnover ratio

Frying System includes following Equipments :

1. Frying System with conveyor belts

2. Continuous Oil Filtration System

3. Oil tank with cooling system

4. Heat Exchanger

5. ID Fan for Heat Exchanger

6. Centrifugal pump for hot oil

7. Electrical control panel dust proof cabinet type

8. Connecting Valves, Pipes and fittings

9. Temperature sensor

10. Motor with Gear to run the conveyor

11. Spares

Technical Specifications :

|

Model

|

MCNF - 300

|

MCNF - 500

|

MCNF - 1000

|

|

Output

|

300 Kg/ Hr

|

500 Kg/ Hr

|

1000 Kg/ Hr

|

|

Fuel Options

|

|

Diesel

|

12Ltr / Hr

|

22 Ltr / Hr

|

42 Ltr / Hr

|

|

Natural Gas

|

13 units / Hr

|

24units / Hr

|

45 units / Hr

|

|

Thermic Fluid

|

50 kg wood/ Hr

|

80 kg wood/ Hr

|

160 kg wood/ Hr

|

|

Wood Based (HE)

|

50 kg wood/ Hr

|

80 kg wood/ Hr

|

160 kg wood/ Hr

|

|

Edible Oil Holding Capt.

|

400 Ltrs.

|

600 Ltrs.

|

850 Ltrs.

|

|

Edible Oil Filtration

|

Drum / Conveyor Filter

|

Drum / Conveyor Filter

|

Drum / Conveyor Filter

|

|

Total Heat Required

|

2,50,000 K Cal

|

4,00,000 K Cal

|

6,00,000 K Cal

|

|

Lifting System

|

Pneumatic

|

Pneumatic

|

Pneumatic

|

|

Floor Space

|

400 Sq. Ft.

|

500 Sq. Ft

|

600 Sq. Ft.

|

|

Material of Construction

|

AISS-304 Grade SS

|

AISS-304 Grade SS

|

AISS-304 Grade SS

|

Dimensions : 20 x 15 Ft

Fuel : Diesel, Gas and Natural Gas

Material of Construction : SS-304 Grade Stainless Steel

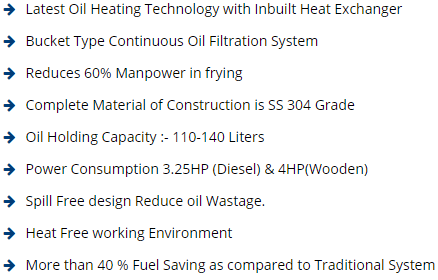

Mini Continuous Fryer or Nano Namkeen Fryer:

This Frying system has following features:

- Latest Oil Heating Technology with inbuilt Heat Exchanger

- Bucket Type Oil Filtration System

- Pneumatic Conveyor Lifting Arrangement for easy cleaning

- Heat Free working Environment

- High oil turnover ratio

|

Dimension

|

9ft x 5ft

|

12ft x 9ft

|

|

Power Consumption

|

4.75HP

|

5.25 HP

|

|

Production Capacity

|

100 Kg/Hr.(Basen Sev, Gathiya etc)

200 Kg/Hr.(Kurkure & Fryems)

|

150 Kg/Hr.(Basen Sev, Gathiya etc)

300 Kg/Hr.(Kurkure & Fryems)

|

|

Oil Holding Capacity

|

150 to 180 Litres

|

200-225 Litres

|

|

Fuel

|

Diesel, LPG or Natural Gas

|

Diesel, LPG or Natural Gas

|

|

Material of Construction

|

AISS-304 Grade Stainless Steel

|

AISS-304 Grade Stainless Steel

|

Frying System includes following Equipments :

- Frying System

- Inbuilt Heat Exchanger

- Oil Storage tank (Capacity-250 Ltr)

- Control Panel with VFD system

- 3 HP Pump with Motor

- Automatic Diesel Burner with Temperature Controller

Dimensions: Length - 9 Feet/ Width - 4.5 Feet

Fuel: Diesel or Gas.

Material of Construction: SS-304 Grade Stainless Steel

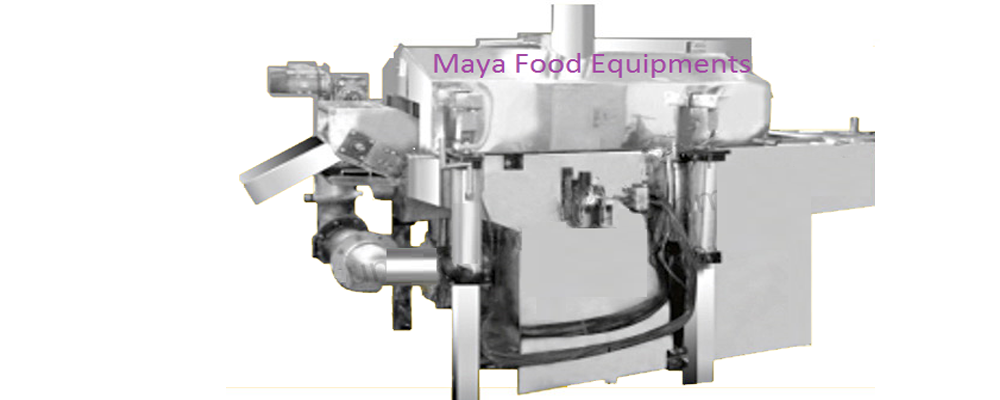

Multiproduct Continuous Fryer (Double Conveyor - Namkeen, Dal Dual System)

|

Our Multiproduct continuous frying system has its unique heating technology that gives you low fuel consumption and good quality finish product. The Multiproduct continuous frying system is suitable for all kinds of Besan based products like Sev Ghathiya, Papdi, Ratlami, Bhavnagri And other floating products

Available in 300 Kg/Hr, 500 Kg/Hr and 1000 Kg/Hr Production Capacity.

|

|

The Frying system has following features:

· Production Capacity 300-350 Kg/Hr (Besan Sev, Ghathiya etc and 180 / 200 kg/hr Chana Dal in same fryer)

· Power Consumption: 8.5 HP

· Fuel Consumption: 11-13 Ltr/Hr

· Oil Holding Capacity:-275 to 400 Litres ( Acording to production Capacity.)

· Latest Oil Heating Technology with Heat Exchanger

· Continuous Conveyer Type Oil Filtration System

· Complete Material of Construction is SS 304 Grade

· Pneumatic Conveyor Lifting Arrangement for easy cleaning

· Heat Free working Environment

· Zero Maintenance Fryer

· Optimal oil turnover ratio

|

|

Frying System includes following Equipments :

- Frying System with conveyor belts

- Continuous Oil Filtration System

- Oil tank with cooling system

- Heat Exchanger

- ID Fan for Heat Exchanger

- Centrifugal pump for hot oil

- Electrical control panel dust proof cabinet type

- Connecting Valves, Pipes and fittings

- Temperature sensor

- Motor with Gear to run the conveyor

- Spares

Dimensions : 20 x 15 Ft

Fuel : Diesel, Gas, Natural Gas, Wood and Biofuel

Material of Construction : SS-304 Grade Stainless Steel

Technical Specifications :

|

Model

|

MCNF - 300

|

MCNF - 500

|

MCNF - 1000

|

|

Output

|

300 Kg/ Hr

|

500 Kg/ Hr

|

1000 Kg/ Hr

|

| |

|

Diesel

|

12Ltr / Hr

|

22 Ltr / Hr

|

42 Ltr / Hr

|

|

Natural Gas

|

13 units / Hr

|

24units / Hr

|

45 units / Hr

|

|

Thermic Fluid

|

50 kg wood/ Hr

|

80 kg wood/ Hr

|

160 kg wood/ Hr

|

|

Wood Based (HE)

|

50 kg wood/ Hr

|

80 kg wood/ Hr

|

160 kg wood/ Hr

|

|

Edible Oil Holding Capt.

|

400 Ltrs.

|

600 Ltrs.

|

850 Ltrs.

|

|

Edible Oil Filtration

|

Drum / Conveyor Filter

|

Drum / Conveyor Filter

|

Drum / Conveyor Filter

|

|

Total Heat Required

|

2,50,000 K Cal

|

4,00,000 K Cal

|

6,00,000 K Cal

|

|

Lifting System

|

Pneumatic

|

Pneumatic

|

Pneumatic

|

|

Floor Space

|

400 Sq. Ft.

|

500 Sq. Ft

|

600 Sq. Ft.

|

|

Material of Construction

|

AISS-304 Grade SS

|

AISS-304 Grade SS

|

AISS-304 Grade SS

|

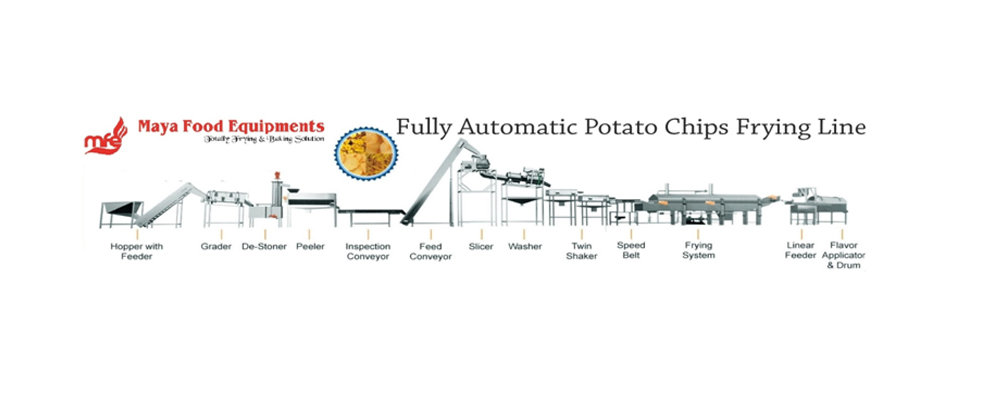

Fully Automatic Chips Frying Line (Potato / Banana, Potato Stick- Salli)

Available with us is a wide range of Potato / Banana Chips Fryer. These are used for frying potato chips and namkeen and other various products. Our fryers have imported italian rielo burner for massive production capacity and for uniform quality.

Integrated automatic production of Potato Chips etc. from raw potatoes; capacity 100/200/300/500 Kg/hr.

The Frying System have following features:

- Low edible oil take up

- Low fuel Consumption.

- Improved productivity with excellent product quality.

- Very low labour requirement.

- Excellent on line oil filtration.

- High oil turnover ratio

- Indirect Heating Arrangement.

- Frying Control

- Continuous Filtration

- Oil Quality

- Air Knife

- Compact Design

Products made by the line are:

- Potato Chips(Plain , Ruffles)

- Potato Sticks(Salli)

Processing System includes following equipments:

- Raw Potato Hopper

- Feeding Elevator

- Potato Size Grader

- De-stoner

- Peeler

- Inspection Conveyor

- Slicer

- Slice Feed Conveyor

- Slice Washer

- Ecentric Shaker 1

- Ecentric Shaker 2

- High Speed Conveyor Belt

- Continuous Frying System with Heat Exchanger

- De-oiling Belt

- Linear Shaker

- Flavor Tumbler & Applicator

- Control Panel

Dimension: 110 x 20 Ft

Power Consumption: 27.0 HP & 35.0 HP

Fuel: Diesel, LPG or Natural Gas

Material of Construction: AISS-304 Grade Stainless Steel

Technical Specifications :

|

Model

|

Chips 300

|

Chips 500

|

Chips 1000

|

|

Output

|

300 Kg/ Hr

|

500 Kg/ Hr

|

1000 Kg/ Hr

|

|

Fuel Options

|

|

Diesel

|

90Ltr / Hr

|

150 Ltr / Hr

|

150 Ltr / Hr

|

|

Natural Gas

|

100 units / Hr

|

180 units / Hr

|

330 units / Hr

|

|

Thermic Fluid

|

400 kg wood/ Hr

|

400 kg wood/ Hr

|

1300 kg wood/ Hr

|

|

Edible Oil Holding Capt.

|

1000 Ltrs.

|

1800 Ltrs.

|

3500 Ltrs.

|

|

Edible Oil Filtration

|

Edible Oil Filtration

|

Edible Oil Filtration

|

Drum / Conveyor Filter

|

|

Total Heat Required

|

9,00,000 K Cal

|

15,00,000 K Cal

|

15,00,000 K Cal

|

|

Water

|

3000 Ltr / Hr

|

5000 Ltr / Hr

|

10,000 Ltr / Hr

|

|

Lifting System

|

Mechanical

|

Mechanical

|

Mechanical

|

|

Floor Space

|

3000 Sq. Ft.

|

4000 Sq. Ft.

|

5000 Sq. Ft.

|

|

Material of Construction

|

AISS-304 Grade SS

|

AISS-304 Grade SS

|

AISS-304 Grade SS

|

Specific Features

- Better Oil Management

- Low Conversion Cost

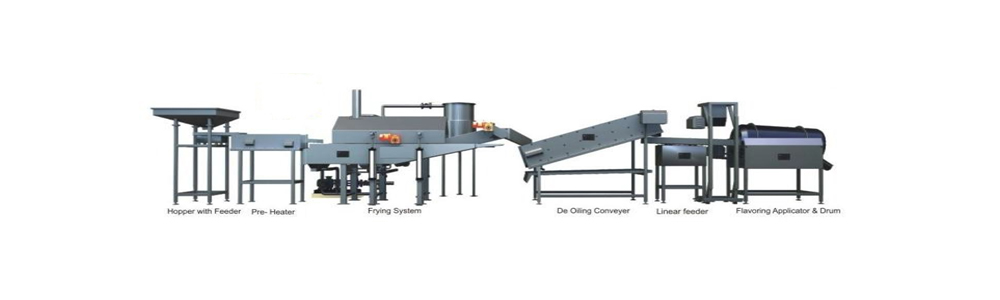

Semi Automatic Continuous Chips Frying Line

Available with us is a wide range of Potato / Banana Chips Fryer. These are used for frying potato chips and namkeen and other various products. Our fryers have imported italian rielo burner for massive production capacity and for uniform quality.

Production Capacity: 100 kg/hour useful for frying of potato chips, Potato Sticks (Salli) & Banana Chips. Also available in 200 Kg/Hr Production Capacity.

The Frying System have following features:

- Production Capacity 100 Kg/Hr Potato Chips/Sticks & Banana Chips

- Fuel Consumption: 26 Ltr/Hr

- Power Consumption: 0 HP

- Oil Holding Capacity: 450 Litres

- Latest Oil Heating Technology with Heat Exchanger

- Continuous Conveyer Type Oil Filtration System

- Complete Material of Construction is SS 304 Grade

- Pneumatic Conveyor Lifting Arrangement for easy cleaning

- Heat Free working Environment

- Zero Maintenance Fryer

- High oil turnover ratio

Frying System includes following equipments:

- Peeler

- Slicer

- Hydro

- Vibro Shaker

- Hopper with Metered Feeder

- Frying System

- Heat Exchanger

- Oil Tank

- Control Panel

- Flavouring Applicator and Drum

- Specifications:

- Dimensions : 20 x 15 Ft

- Fuel : Diesel, LPG, Natural Gas

- Material of Construction : AISS-304 Grade Stainless

Fully Automatic Pallets Frying Line

We are in instrumental in offering a wide array of Pellet Frying Line. These are fabricated using high quality material and are widely appreciated by our clients. Further, these are available in customized form as well so as to meet the demands of the clients.

- Our Pallets Frying Line are efficient and cost effective. We use premium material & latest technology to ensure our clients get more improved quality range. Also, the products are customized to meet the varied requirements for our clients.

Available with Diesel Heat Exchanger and Wooden Heat Exchanger and direct Heating.

Production Capacity: 150, 200, 500,1000, 1500 Kg/hr

Two Models :

- Direct Heating Pellets Fryer

- With Heat Exchanger Pellets Fryer

Pallets Frying Line includes following Equipments:

- Vibratory Feeder with Hopper

- Continuous Frying System with Continuous Oil Filtration and Heat Exchanger

- Oil Tank with Cooling System

- De-oiling Conveyer

- Linear Feeder

- Flavor applicator & Drum

- Control Panel

Production Capacity: 500 Kg/Hr

Dimensions : 45 x 15 Ft(with diesel heat exchanger),

45 x 15 Ft(with wooden heat exchanger)

Power Consumption: 15 HP (with diesel heat exchanger),

17.5 HP (with wooden heat exchanger)

Fuel: Diesel, LPG, Natural Gas or Wood/Biofuel

Material of Construction : AISS-304 Grade Stainless Steel

Specifications:

- Finished product quality

- low edible oil take up

- No more man power requirment

- Excellent on line oil filtration system

Power Consumption: 9 HP to 14HP According to production capacity

Technical Specifications :

|

Model

|

Pallets - 300

|

Pallets - 500

|

Pallets - 1000

|

Pallets - 1500

|

|

Output

|

300 Kg/ Hr

|

500 Kg/ Hr

|

1000 Kg/ Hr

|

1500 Kg/ Hr

|

|

Fuel Options

|

|

|

Diesel

|

5-6 Ltr / Hr

|

8-10 Ltr / Hr

|

17-20 Ltr / Hr

|

28-30 Ltr / Hr

|

|

Natural Gas

|

6-7 units / Hr

|

10-12 units / Hr

|

20-22 units / Hr

|

30 units / Hr

|

|

Thermic Fluid

|

25 kg wood/ Hr

|

40 kg wood/ Hr

|

80 kg wood/ Hr

|

120 kg wood/ Hr

|

|

Wood Based (HE)

|

25 kg wood/ Hr

|

40 kg wood/ Hr

|

80 kg wood/ Hr

|

120 kg wood/ Hr

|

|

Edible Oil Holding Capt.

|

250-300 Ltrs

|

450-500 Ltrs

|

700-800 Ltrs

|

1000-1200 Ltrs

|

|

Edible Oil Filtration

|

Drum / Conveyor Filter

|

Drum / Conveyor Filter

|

Drum / Conveyor Filter

|

Drum / Conveyor Filter

|

|

Heat Requirement

|

1,00,000 K Cal

|

2,00,000 K Cal

|

3,00,000 K Cal

|

4,00,000 K Cal

|

|

Total Power Required

|

7 HP

|

9 HP

|

13 HP

|

18 HP

|

|

Lifting System

|

Pneumatic / Screw

|

Pneumatic / Screw

|

Pneumatic / Screw

|

Pneumatic / Screw

|

|

Floor Space

|

1200 Sq. Ft.

|

1500 Sq. Ft.

|

1500 Sq. Ft.

|

2000 Sq. Ft.

|

|

Material of Construction

|

AISS-304 Grade

|

AISS-304 Grade

|

AISS-304 Grade

|

AISS-304 Grade

|

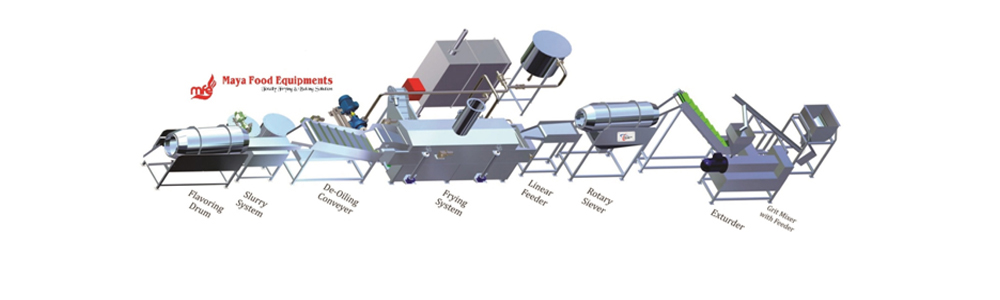

Fully Automatic Kurkure Production Line

Fully Automatic Kurkure Production Line is capable of integrated automatic production Kurkure from raw grit.

Production Capacity : 150, 300 and 500 Kg/Hr

Dimensions : 50 x 15 Ft

Fuel : Diesel, LPG, Natural Gas or Wood/Biofuel

Material of Construction : AISS-304 Grade Stainless Steel

Processing Line includes following Equipments:

1. Grit Mixer cum Feeder

2. Kurkure Extruder

3. Feeding Elevator

4. Rotary Siever

5. Continuous Frying system with Heat Exchanger

6. De-oiling Belt

7. Linear Feeder

8. Flavor Applicator & Drum

9. Slurry System

10. Control Panel

Technical Specifications:

|

Model

|

Kurkure - 300

|

Kurkure - 500

|

|

|

Output

|

300 Kg/ Hr

|

500 Kg/ Hr

|

|

|

Fuel Options

|

|

Diesel

|

9 Ltr / Hr

|

15 Ltr / Hr

|

|

|

Natural Gas

|

11 units / Hr

|

19 units / Hr

|

|

|

Thermic Fluid

|

40 kg wood/ Hr

|

70 kg wood/ Hr

|

|

|

Edible Oil Holding Capt.

|

250 Ltrs.

|

450 Ltrs.

|

|

|

Edible Oil Filtration

|

Drum Filter

|

Drum Filter

|

|

|

Heat Requirement

|

1,50,000 K Cal

|

3,00,000 K Cal

|

|

|

Total Power Required

|

75 HP

|

90 HP

|

|

|

Lifting System

|

Pneumatic / Screw

|

Pneumatic / Screw

|

|

|

Floor Space

|

1500 Sq. Ft.

|

2000 Sq. Ft.

|

|

|

Material of Construction

|

AISS-304 Grade

|

AISS-304 Grade

|

|

Features:

- Low edible oil take up

- Low fuel Consumption.

- Improved productivity with excellent product quality.

- Very low labour requirement.

- Excellent on line oil filtration.

- High oil turnover ratio

- Indirect Heating Arrangement

Batch Type Kurkure Production Line

Kurkure Extruder Rectangular Fryer

|

Production Capacity:

· Kurkure and Fryems: 200 Kg/hr

· Pan Size: 4 x 2 feet / 4.6 x 2.6 feet

|

The Frying System have following features:

· Low Fuel Cost, almost 20-30% less as compared to traditional system.

·Low Electricity Cost, 80% less as compared to traditional system

·Automatic temperature control that provide better and consistent product quality.

· Auto Ignition Italian burners are fitted for Heating

|

French Fries / Finger chips Production Line

We offer three types of French Fries production machinery with capacity as per customers' requirements (50,100,200,500 Kg/Hr.).

1. Batch Type French fries Production machinery:

- Potato Peeler cum Washer

- French Fries Slicer

- Blancher (optional)

- Dryer

- Batch Fryer (Diesel/Gas/Wooden)

- De-oiling Dryer

2. Semi-Automatic Continuous French Fries Production Line:

- Potato Peeler cum Washer

- French Fries Slicer

- Blancher optional

- Dryer

- Vibratory feeder for French fries

- Automatic Continuous French Fries Fryer system

- De-oiling Conveyor

3. Fully Automatic Continuous French Fries Production Line

Rectangular Fryer with Tilting Arrangement with Wooden Heat Exchanger

Maya Food Equipment presents Rectangular fryer with Diesel and Wooden Based Dual Heating System in same Machine.

- Dimension : Pan Size - 4'6" x 2.6" x 10"

- Filteration System: Bucket Type Oil Filter

- Capacity Of System : wooden Based Heat Exchanger

- Application : Namkeen / Wafer / Dal

Products Production Capacity

Potato Chips 50-55 Kg/Hr

Moong Dal 90-95 Kg/Hr

Channa Dal 100-110 Kg/Hr

Banana chips 50– 55 Kg/Hr

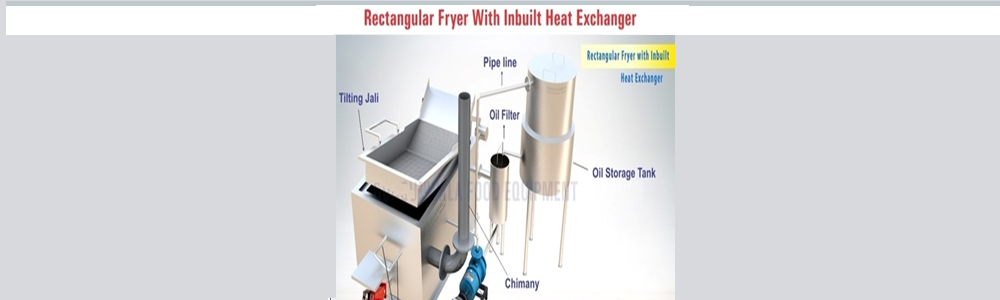

Rectangular Fryer with Tilting Arrangement with inbuilt Heat Exchanger (diesel/gas burner)

Maya Food Equipments presents a new revolution in frying technology for Chips , Dals, Vatana and other products require high heat requirement, It is a new Rectangular fryer with a combination of Direct & Indirect heating gives you a more than 55% saving in Fuel and double the production capacity.

The Rectangular Fryer is having following features:

- Latest Oil Heating Technology with Inbuilt Heat Exchanger

- Bucket Type Continuous Oil Filtration System

- Reduces 60% Manpower in frying

- Complete Material of Construction is SS 304 Grade

- Oil Holding Capacity: 110-140 Liters

- Zero Maintenance Batch Fryer

- Power Consumption 3.25 HP

- Spill Free design Reduce oil Wastage.

- Heat Free working Environment

- More than 55 % Fuel Saving as compared to Traditional System

- Payback period is 3-4 months.

Technical specification

|

Products

|

Production Capacity

|

Fuel Consumption

|

|

Potato Chips

|

50-55 Kg/Hr

|

11-12 Ltr/Hr

|

|

Moong Dal

|

90-95 Kg/Hr

|

11-12 Ltr/Hr

|

|

Channa Dal

|

100-110 Kg/Hr

|

11-12 Ltr/Hr

|

|

Banana chips

|

50– 55 Kg/Hr

|

11–12 Ltr/Hr

|

Rectangular Fryer with Tilting Arrangement - Direct Heating (diesel/gas burner)

The Rectangular Fryer is product in the intermediate range between the Batch Type & Continuous Fryers. The unique feature of this fryer is its tilting system that enables unloading of products in a single stroke after frying for uniform & consistent product quality

Application :

This fryer is best suited for low bulk density products such as corn flakes, rice flakes, kurkure (Nicknack),pellets, onion flakes etc

The Frying System have following features

- Low fuel cost almost 20-30% less as compared to traditional system (Bhatti).

- Low Electricity cost, 80% less as compared to traditional system

- Automated temperature control that provide better and consistent product quality.

- Highly Environment friendly process.(Minimal Noise & air pollution).

- High hygiene quotient

- Auto ignition

Italian burners are fitted for heating

Rectangular Fryer with Tilting Arrangement with Direct Heating (Wooden/Pallets/Biofuel based)

The Rectangular Fryer is product in the intermediate range between the Batch Type & Continuous Fryers. The unique feature of this fryer is its tilting system that enables unloading of products in a single stroke after frying for uniform & consistent product quality

Application :

This fryer is best suited for low bulk density products such as corn flakes, rice flakes, kurkure (Nicknack), pellets, onion flakes etc

The Frying System have following features

- Low fuel cost almost 20-30% less as compared to traditional system (Bhatti).

- Low Electricity cost, 80% less as compared to traditional system

- Automated temperature control that provide better and consistent product quality.

- Highly Environment friendly process. (Minimal Noise).

- High hygiene quotient

- Auto on off blower connected with temperature sensor through control panel.

You can directly use woods, pallets, boifuel as fuel to burn and heat.

Circular Fryer with Tilting Arrangement with Wooden based Heat Exchanger

Maya Food Equipment presents Circular fryer with Diesel and Wooden Based Dual Heating System in same Machine.

- Dimension: Pan Size: 42” / 45” / 48” / 54”

- Filtration System: Bucket Type Oil Filter

- Capacity Of System : wooden Based Heat Exchanger Application : Namkeen / Wafer / Dal

|

Products

|

Production Capacity

|

|

Sev Gathiya papdi and other Besan based products

|

120-130 Kg/Hr

|

|

Kurkure and Fryums

|

250 Kg/Hr

|

|

Potato Chips

|

40-45 Kg/Hr

|

|

Moong Dal

|

80-85 Kg/Hr

|

|

Channa Dal

|

80-85 Kg/Hr

|

|

Banana chips

|

40-45 Kg/Hr

|

Specifications:

Circular Fryer with Tilting Arrangement with inbuilt Heat Exchanger (diesel/gas burner)

Maya Food Equipments presents a new revolution in frying technology for Chips, Dals, Vatana and other products require high heat requirement. It is a new circular fryer with a combination of Direct & Indirect heating gives you a more than 55% saving in Fuel and double the production capacity. We offer 48" Circular Fryer.

Also available in without tilting system

The system is consist of:

- SS-304 Pan Diameter 48"

- Italian Ecoflam Burner (Diesel/ Gas)

- Electric panel board with temperature controller

- Bucket type automatic edible oil filter system

- Inbuilt Heat Exchanger

- 3 HP Pump & motors

The Circular Fryer is having following features:

- Latest Oil Heating Technology with Inbuilt Heat Exchanger

- Bucket Type Continuous Oil Filtration System

- Reduces 60% Manpower in frying

- Complete Material of Construction is SS 304 Grade

- Oil Holding Capacity: 110-140 Liters

- Zero Maintenance Batch Fryer

- Power Consumption 3.25 HP

- Spill Free design Reduce oil Wastage.

- Heat Free working Environment

- More than 55 % Fuel Saving as compared to Traditional System

- Payback period is 3-4 months.

Technical specification:

|

Products

|

Production Capacity

|

Fuel Consumption

|

|

Potato Chips

|

50-55 Kg/Hr

|

11-12 Ltr/Hr

|

|

Moong Dal

|

90-95 Kg/Hr

|

11-12 Ltr/Hr

|

|

Channa Dal

|

100-110 Kg/Hr

|

11-12 Ltr/Hr

|

|

Banana chips

|

50– 55 Kg/Hr

|

11–12 Ltr/Hr

|

|

Sev Gathiya Papdi and other besan(Gramflour)based products

|

150-175 Kg/hr

|

7-10 ltr /hr

|

Circular Fryer with Tilting Arrangement with Direct Heating (diesel/gas burner)

- Circular Batch Fryer is made of SS 304 with tilting arrangement that enables unloading of Products in a single stroke after frying.

- There is an additional Collar arrangement added in the fryer to avoid Spillage of edible oil during frying.

|

Sr. No.

|

Pan Dia

|

Type of Extruder

|

Products

|

Capacity

|

|

1

|

12"

|

N.A.

|

Soan Papdi

|

40 kg sugar/hr.

|

|

2

|

18"

|

Hand Driven

|

Bikaneri Bhujiya & Mava

|

20 to 25 kg/hr.

|

|

3

|

24" & 30"

|

Hand Driven

|

Nylon Sev, Garlic Sev, Samosa, Kachori

|

20 to 35 kg/hr.

|

|

4

|

36"

|

Moter Driven

|

Papdi, All Types Gathiya & Sev

|

35 to 40 kg/hr.

|

|

5

|

42"

|

Motor Driven

|

Chana, Mung Dal, Coated Peanuts

|

40 to 50 kg/hr.

|

|

6

|

60"

|

Motor Driven

|

Potato Wafer, Banana Wafer

|

50 to 60 kg/hr.

|

Circular Fryer with Tilting Arrangement with Direct Heating Wooden/Pallets/Biofuel based

Pan sizes available: 24”, 30”, 36”, 42”, 45”, 48”

The Circular Fryer is product in the intermediate range between the Batch Type & Continuous Fryers. The unique feature of this fryer is its tilting system that enables unloading of products in a single stroke after frying for uniform & consistent product quality

Application :

Namkeen, Sev, Gathiya, papadi, pellets , Potato chips , Banana Chips, Indian Traditional Nankeens and all kind of Fryms etc

The Frying System have following features

The Frying System have following features

- Low fuel cost almost 20-30% less as compared to traditional system (Bhatti).

- Low Electricity cost, 80% less as compared to traditional system

- Automated temperature control that provide better and consistent product quality.

- Highly Environment friendly process. (Minimal Noise).

- High hygiene quotient

- Auto on off blower connected with temperature sensor through control panel.

You can directly use woods, pallets, boifuel as fuel to burn and heat.

Namkeen Sev Extruder (NE)

- Machine is fitted over the Fryer fitted with 1.5 H.p. Motor.

- All type of Sev, Gathiya, Papdi, Ratlami Sev, Bhavnagri etc. can be made.

- Various Types of Namkeens can be made by just Changing the Sieve (jali)

- This Extruder can also be used for Crushing Boiled Potatoes for Aloo Bhujia.

- S. Body, Die Size 9" Inch.

- H*L*B: 400*1050*250

- Weight 75 kg approx.., 1.5 hp Motor

- Production capacity 120 kg per hours

- 8 jali with Stand

- Operated by only one un-skilled labour

- Power consumption: 1 HP=1 unit/hr

Other Size available: 7 inch, 9 inch and 12 inch

Continuous Namkeen Sev Extruder

- Maya Food Introduces Continuous Namkeen Extruder with production capacity 300 kg/hr, 500 kg/hr, 1000 kg/hr.

- Two heavy duty motors with gear for smooth operation.

Material of construction SS 304.

Continuous Zero or Nylone Sev Making Machine

- Maya Food Introduces Continuous Zero or Nylone Sev.

- Capacity 150 Kg per hr / 50 kg per hr.

- Two heavy duty motors with gear for smooth operation.

Material of construction SS 304

Dough / Atta Making Machine:

- It is used for making Besan Dough for Namkeen also for Chappatis.

- The flour is loaded from the top along with ingredients.

- This Kneads 20 kg flour in 10 minitues.

- S. Body, S.S. Bowl, Varam S.S

- Kadai Size: D*H - 22" *15"( Mixing Bowl is 15’’ deep and internal diameter is 22”)

- H*L*B: 1000* 1000 *550

- 5 hp Motor/ 3 phase

Other Size available:

- 10 kg, s.s. bowl, 1 hp motor

40 kg, s.s. bowl, 3 hp motor

Potato Peeler

- This Machine removes the skin from Potatoes i.e. The equipment peels potatoes with minimum peel loss.

- Water is sprayed on the product for better peeling. Peel waste is carried away with water and flows to drain.

- Fine carborundum black emery is embedded inside the drum which removes the skin from the walls.

- This processing requires minor flow of water through a pipe to remove the skin from the walls

- Dimensions: HLB: 850* 900* 600

- Motor :– 1 HP; 3 Phase

- RPM :– 1440

- Weight : - 80 Kg. Approx.

Capacity : - 7-8 Kg/Batch.

Potato Cutter / Slicer or Potato Chips / Wafer Making Machine

- It is a top feeding type slicer, which can produce plain, ruffles and potato sticks. There is a provision to adjust slice thickness.

- This is self-pressing type model, the potatoes are fed from the top of the machine.

- Continuous water supply is given to equipment to avoid deposition of broken Pisces in Dye.

- This machine comes with three basic cutter, Plain chips, Ruffels.

- Available in two models with capacity 400 kg per hours.

- Dimensions: 3 x 3 x 3 Ft(approx. HLB: 950* 600* 400)

- Motor: 1 HP Three Phase

- Weight: - 65 Kg. Approx.

- Dye: 2 Dyes (Ruffles or Plain )

- MOC: S. body, M.S. stand

- Weight 65 kg approx.

100kg/hr capacity also available.

Hydro / Dryer Machine

- Drayer is used to remove excess oil / water from Namkeen & Sliced Potato wafers.

- The equipment removes excess surface water from the slices and separates them prior to frying. Hydro is made of S.S. with proven technology.

- It has a rotating basket in which the products which has to be dried is placed, after a spin for few minutes product is dried.

- S. Body, M.S. Bottom

- The Basket/ Drumsize: D*H15"*12"

- H*L*B: 700*1100*650(approx.: 28” x 18” x 30”)

- Motor Requirements 1 hp, 3 phase.

- RPM: 1440

Machine Weight 90 kg approx

Coating pan

- 36" size, 1 H.P. Motor

- This is Specially Designed to apply Seasoning to fried Product in uniform manner

- Capacity 10-15 kg per batch of 8 min.

- Motor Requirement 1 hp, 3 Phase.

- All Contact parts S.S. Bowl , M.S. body,

- Available in various capacities.

Other Size available:

35 - 40 Kg per Batch

Drum type Chips Masala Coating Machine:

- Drum Size:

- Diameter: 4 ft.

- Depth: 2 ft.

- Tilting type coating machine

Coating masala or flavors to Chips or other similar products

Namkeen or Farsan Mixing Machine:

- An U shape pan made of SS 304 contact part with lifting arrangement for mixing different products uniformly, the mixing will be done uniformly in a single batch. This pan is mounted on SS/MS frame.

- Body: S.S.

- Size ( h x l x w): 41 x 60 x 26

- Weight: 200 kg

- U shape bowl

- production capacity: 50 kg/7min

- Electric Motor: 1.5 H.P.

- Speed: 1440 rpm

- Application: For mixing Masala, chavanu, chevdo, vegetables, frymes, etc.

Other Sizes available:

- Farshan/Namkeen Mixer Machine 2 Ft.:

- Farshan/Namkeen Mixer Machine 3 Ft.:

- Farshan/Namkeen Mixer Machine 5 Ft.: Motor: - 5 HP, 3 Phase with Italian geared Motor.

Capacity: - 120 Kg/Batch

Banana Wafer Machine:

- This machine is used for slicing bananas as plain Chips & Rippled Chips.

- Peeled bananas fed manually from the top, Sliced chips are guided through a guide, fitted over a frying pan.

- 5 hp DC motor, S.S. body

- 3 dies Round, Ovel, Long patta

- HLB 475 * 500* 375 or 26 x 28 x 12 in.

- Weight 50 kg approx.

- Production Capacity: 500 kg/hr.

- Speed: 960 rpm

- Power Consumption: 75 unit/hr.

- Banana Wafer shape: 3 dies available

- Shape: Small round, Medium slice(Cross or Capsule) & long Slice

Dal Washer (DW-20):

- Fabricated using solid and superior quality of SS, our Dal Washer is manufactured following adequate measures to maintain hygiene of the machineries. Both washing and soaking processes are done simultaneously to get best quality of fried dal.

- Motor: - 5 HP, 3 Phase with Italian geared Motor.

- Material of Construction: - All Contact part are made of SS 304.

- Capacity 120-130 Kg per batch

5 Minutes for Channa dal and 12-15 min for Moong dal

Kurkure Extruder:

- Maya Food Introduces Continuous Kurkure Extruder.

- Available in various capacities.

- Material of construction SS / MS.

Spiral Mixture 15/30/60/90 KG:

- Spiral Mixer Machine offer a complete, smooth and lump free preparation of dough. The mixer can mix up any kinds of dough and can be operated on limited but variable speeds for quality processing.

- It is used for making Besan / Maida Dough for Bhujiya /Namkeen/bakery products.

- The flour is loaded from the top along with ingredients.

- Capacity Kneads 30 kg flour per batch

- S. Body, S.S. Bowl and Spiral

- Mixes with double speed

- Reverse & forward function

Emergency stop with safety grill